Premium DC Motor Drives: Reviews of Top Brands for Enhanced Performance

High-quality drive solutions for DC motors are available from our factory, which specializes in manufacturing durable gear DC motors suited for various applications. As a trusted manufacturer, we provide competitive wholesale pricing for bulk orders. With over ten years of industry experience, we effectively cater to your needs. Our advanced equipment and skilled engineers produce outstanding products recognized for their performance and longevity. Our strong R&D team stays ahead of technology trends, offering innovative solutions that enhance your projects. Choose us for your high-quality DC Motor Drives and see the difference a committed manufacturing partner can make. Whether you require specific customizations or want to place a large order, we are committed to supporting you with expert technology and dedicated service. Together, we can elevate your business!

Key Methods For High-Quality Drive For Dc Motor Dominates For the Current Year

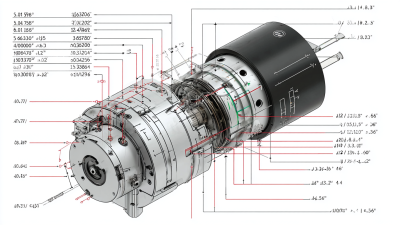

In today's ever-evolving market, ensuring exceptional performance from DC motors is critical for manufacturers and users alike. At our company, we take pride in our extensive experience in producing high-quality gear DC motors. Our robust R&D team continuously innovates, leveraging advanced technology and equipment to enhance motor performance. This dedication empowers us to meet the diverse demands of global buyers effectively. One key method for achieving high-quality drive for DC motors is the meticulous design process we employ. Our skilled engineers focus on optimizing motor efficiency, durability, and performance. By testing various materials and configurations, we ensure our motors are not only reliable but also cost-effective for your applications. Furthermore, our commitment to quality control means that every motor undergoes rigorous testing before it reaches our customers, guaranteeing top-tier performance. In addition to superior products, we offer our clients professional technical support. Our team's expertise extends beyond manufacturing; we collaborate closely with customers to understand their unique requirements and provide tailored solutions. This comprehensive approach makes us a partner of choice for businesses looking to enhance their operations with high-quality DC motors. Connect with us today to learn more about how we can support your motor needs.

Key Methods For High-Quality Drive For DC Motor Dominates For the Current Year

| Method | Description | Advantages | Applications |

|---|---|---|---|

| Pulse Width Modulation (PWM) | A technique used to control the amount of power delivered to the motor by varying the width of the pulses in a pulse train. | High efficiency, reduced heat generation, precise control. | Robotics, fans, and automotive applications. |

| Field Weakening | A method to increase the speed of a DC motor by decreasing the magnetic field strength. | Increased speed range, high-speed applications. | Electric vehicles, industrial tasks. |

| Closed Loop Control | An automated control system that uses feedback to ensure optimal performance. | Higher accuracy, better response to disturbances. | CNC machines, conveyor systems. |

| Sensorless Control | A method that estimates motor parameters without the need for physical sensors. | Cost-effective, reduced complexity. | Home appliances, small robotics. |

| Current Control | Technique to control the current flowing through the motor to prevent overheating. | Enhanced motor longevity and performance. | Electric vehicles, power tools. |

The Secret to High-Quality Drive For Dc Motor Products Where Innovation Meets 2025

I

Isabella Harris

This product has really impressed me. The staff’s professionalism during the purchase process was a breath of fresh air.

17 June 2025

S

Sofia Allen

Incredible quality! The support team demonstrated impressive knowledge and responded timely.

12 May 2025

C

Chloe Wright

Excellent craftsmanship! The after-sales service was comprehensive and pleasant.

24 May 2025

O

Oliver Reed

Excellent quality! The proactive customer service made me feel valued.

08 May 2025

N

Nora Johnson

Very pleased! The quality control is evident, and the support team was exceptional.

10 May 2025

R

Riley Parker

Fantastic quality product! Very responsive support team handled my inquiries very well.

28 May 2025