In the evolving landscape of motor technology, understanding the "Various Types Of DC Motors" is essential for optimal application. By 2026, the market for electric motors is projected to grow significantly, reaching over $160 billion globally, according to industry reports from Markets and Research. This growth is driven by increasing demand across numerous sectors like automotive, aerospace, and robotics.

Industry expert Dr. John Carter, a leading figure in motor technology, states, "Choosing the right type of DC motor can drastically enhance efficiency and performance." This highlights the importance of selecting the appropriate motor type. Different applications require tailored solutions, and not all DC motors are ideal for every purpose. For instance, brushed DC motors are renowned for their simplicity, while brushless variants offer superior efficiency.

Applying the correct type of DC motor can lead to substantial improvements in energy consumption and operational lifespan. Still, many businesses overlook this critical selection process, leading to inefficiencies. Companies must ensure they understand the nuances of various motors to avoid costly mistakes. In this guide, we delve into the top types of DC motors that will shape the industry in 2026.

As we dive into the trends of 2026, DC motors continue to revolutionize various applications. Today, there are several types, each suited for specific tasks. Brushed motors remain popular for simple tasks due to their ease of use. Brushless motors are gaining traction for their efficiency and lifespan.

In industrial settings, stepper motors are leading in precision control for automation. They provide exact positioning, ideal for robotics. Servo motors are also noteworthy, delivering rapid responses and high torque. These motors fit well in applications requiring accuracy and speed.

**Tip:** When choosing a DC motor, consider the load and speed requirements. Understanding your application will help you select the right motor type.

Another area of growth is the integration of smart technology in DC motors. IoT-enabled motors allow for better monitoring and control. However, this innovation isn’t without challenges. Connectivity issues can lead to maintenance complications.

**Tip:** Always ensure compatibility between your motor and control system. Research wireless technology options for stable communication. Remember, embracing new tech means adapting to constant changes.

In 2026, DC motors are essential in various industries. Their adaptability makes them ideal for numerous applications. In manufacturing, DC motors power conveyor belts, adjusting speed based on demand. Factories rely on them for precise control in robotics. This flexibility can enhance production efficiency, but it also requires careful calibration.

In the automotive sector, DC motors drive components like windows and seats. They ensure smooth operation, improving user experience. Electric vehicles increasingly depend on these motors for traction and braking systems. However, optimizing energy use in such applications remains a challenge. The balance between power and efficiency can be tricky.

Medical devices also utilize DC motors. They help in critical machinery like pumps and surgical tools. Precision is paramount in these situations. Yet, any failure can have serious consequences. Hence, the quality assurance process must be rigorous. The integration of DC motors in diverse fields highlights their importance while raising questions about reliability and performance.

In the world of DC motors, performance metrics define their utility. Brushed DC motors excel in simplicity. They contain brushes that connect through a commutator. This setup makes them easier to control. However, these motors wear out faster. The brushes create friction. Maintenance is often required, which can lead to downtime.

Brushless DC motors, in contrast, have no brushes. Their performance is generally superior. They run smoother and quieter. This design leads to higher efficiency. Less energy is wasted as heat. The lifespan of brushless motors is longer. Yet, they tend to be pricier and more complex to control. Some users fear the initial investment. The benefits usually outweigh the costs over time.

Choosing between the two depends on the application. For small, low-cost projects, brushed motors might suffice. But for advanced applications, brushless motors will shine. Not all projects benefit equally from the two types. Evaluating the specific needs is essential. Be aware of the trade-offs. Balancing performance with cost is critical.

| Motor Type | Torque (Nm) | Speed (RPM) | Efficiency (%) | Maintenance |

|---|---|---|---|---|

| Brushed DC Motor | 0.5 - 50 | 1000 - 5000 | 75 - 85 | High, requires regular maintenance |

| Brushless DC Motor | 1 - 100 | 1000 - 30000 | 85 - 95 | Low, minimal maintenance required |

| Coreless DC Motor | 0.01 - 5 | 3000 - 100000 | 70 - 90 | Moderate, depends on construction |

When it comes to DC motors, understanding efficiency ratings is crucial. Efficiency measures how well a motor converts electrical power into mechanical energy. Higher efficiency means less wasted energy, which translates to better performance and cost savings.

Performance standards vary based on application. A motor designed for robotics might prioritize speed. In contrast, a motor for a fan may focus on torque. Both require careful consideration of their operational environment. Choosing a motor without understanding its application can lead to underwhelming results.

**Tip:** Always check the efficiency rating before purchase. Look for motors with ratings above 80% for optimal performance.

Motor performance can be affected by external factors. Temperature, humidity, and load can all influence efficiency. Regular maintenance is vital to ensure a motor operates at its best. Over time, wear and tear can impact performance.

**Tip:** Keep your motors clean and free of debris. This simple step can greatly enhance their efficiency.

Choosing the right DC motor involves more than just numbers. It requires an understanding of how performance interacts with specific applications. Reflecting on these aspects will lead to more informed decisions.

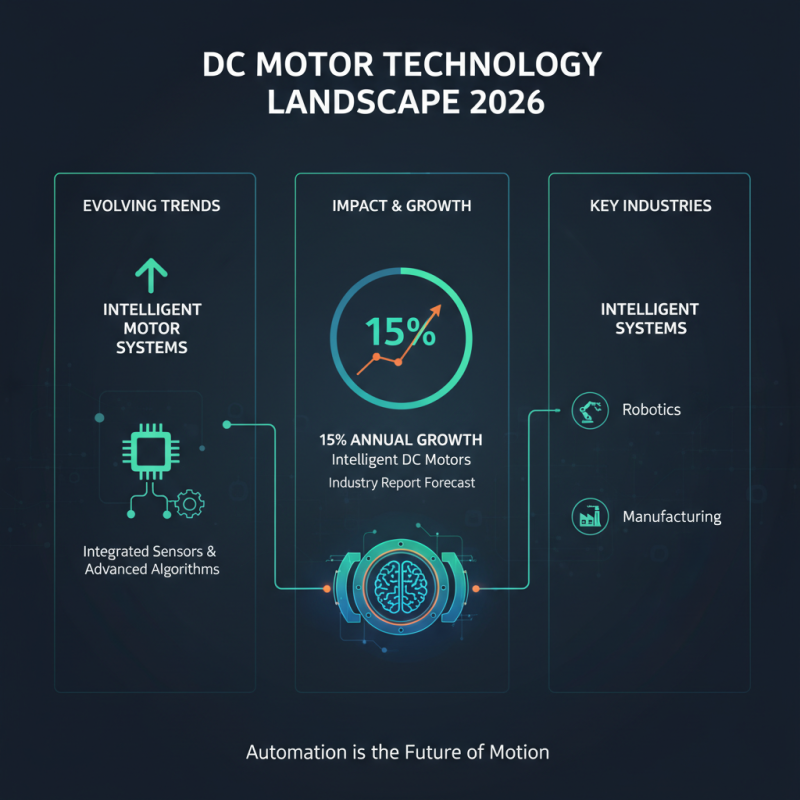

As we look towards 2026, the landscape of DC motor technology is rapidly evolving. One significant trend is the rise of intelligent motor systems. These systems integrate sensors and advanced algorithms, enhancing performance. According to a recent industry report, intelligent DC motors could see a growth rate of 15% annually. This leap signifies a move towards automation in various industries, including robotics and manufacturing.

Additionally, the push for energy efficiency is reshaping motor design. The demand for eco-friendly solutions drives innovation. Industry experts predict that the use of high-efficiency DC motors will increase by 20% by 2026. However, the challenge remains in balancing efficiency with cost-effectiveness. Manufacturers must consider the increased production costs of these advanced technologies. Implementing more efficient designs may lead to higher initial investments, but ultimately promises greater savings.

Lastly, besides energy efficiency, the impact of materials research cannot be overlooked. New materials can enhance performance and durability. The integration of lightweight materials could improve motor efficiency. However, the challenge lies in sourcing these materials sustainably. Transitioning to newer technology will require time and investment. The path forward is not without obstacles, yet the potential is vast.